| 默认排序 | 总价 | 销量 | 评论 | ¥ - ¥ 确定 | 确定 |

| 产品名称 | 产品类别 | 产品简介 | 市场价 | 价格 |

|---|---|---|---|---|

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

|||

|

¥0.00 |

¥0.00 |

- 暂无相关记录!

挑片、装盒 - 与 Micross 合作的裸芯片产品与服务

取放(分拣)基本概念

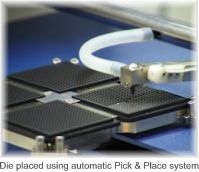

圆片一经划开,管芯的仔细处理对于整体质量和提高管芯成品率是极其重要的.由于产品的精密性(特别是管芯的活性面),利用取放机器,使我们能用绝对小的接触和相应的吸力把管芯从带环形框架的薄膜上取下.尽管有些地方做一点手工移动是必要的,但选择通过取放机器来自动处理总是可取的,因为这大大降低了对管芯造成机械损坏的可能性,取和放的自动化对于大批量生产也是必要的,同时能提供快速的交货周期,否则这简直是不可能的!微小的三极管管芯可以作为一个很好的例子,即使我们最熟练和最有经验的洁净室工人,也不能在一小时之内手工取放1750个管芯。最后,自动取放机器的使用也使我们能够保证管芯100%定向,这样能保证与最终用户的其它设备完全兼容,适合再次高速生产的要求。

取放(分拣)—工艺过程

划过的圆片仍然留在环形框架上,并且被固定在分拣机中央的圆盘上.拉伸支撑圆片的金属薄片以增加管芯之间的距离.通过观察显示屏,操作者可以手动调整管芯的X和Y坐标使管芯位于显示屏中央.实际上,从薄膜上分离管芯是通过使用单只或多只顶针来实现的,顶针从薄膜的下面往上推,利用在背后加压力的方法来分离管芯.为了拾取这些顶起的管芯,一个带真空吸嘴的机械臂移动到管芯上方,拾取管芯并把它放入适当的载器里。虽然要求先对分拣机校准和设置,而一旦完成校准和设置后,操作工就能快速而有序地把管芯一个个从薄膜上取下并放置到输出载器里。

取放(分拣)—能力

Royce Instruments Inc. Model DE35挑片机,彩色图像放大

精密地管芯取放操作

可分拣直径6”(150mm)的圆片

可分拣从0.008”至0.6”以上大小的芯片

安全取放应用于倒装芯片的带突起管芯

管芯可被分类放置在芯片盒或非真空料盒(胶装盒)中

管芯自动定位

大批量订单可以快速交货

- 购买人 会员级别 数量 属性 购买时间

- 商品满意度 :

-

邮编:518055

Copyright © 1992-2026

粤ICP备07034145号